Key Features of 4A Medical Sterilization Pouches

Sterilization pouches are produced by bonding two main components, such as paper and plastic film, together using heat treatment or adhesive tape. Medical-grade paper or Tyvek® is used in the paper section of sterilization pouches.

The plastic part is made of a transparent polypropylene/polyester laminated film for medical-grade paper and a polyethylene/polyester laminated film for Tyvek®. The plastic side of the pouch allows for a clear view of the product inside and the chemical indicator on the edges of the pouch.

The paper part is designed to allow the penetration of chemical gas or steam in the sterilizer and the removal of air. Medical-grade paper is used for Steam, EO (Ethylene Oxide), or FO (Formaldehyde) gas sterilization. Tyvek® is used for Hydrogen Peroxide ($H_2O_2$) sterilization, also known as EO and plasma sterilization. Additionally, Tyvek® is used for alternative sterilization methods such as Ozone and Gamma sterilization.

The chemical indicators on the edges of sterilization pouches are Class 1 indicators that measure whether a sterilization parameter, such as exposure to steam or chemical gas, has been met. If the sterilization parameter is met, the chemical indicator changes color.

Why Should You Choose 4a Medical Products?

4A Medical'i tercih etmek; kanıtlanmış kaliteye, kapsamlı ve yenilikçi çözümlere ve hasta güvenliğine en üst düzeyde önem veren bir iş ortağına yatırım yapmak demektir. Tıbbi cihazlarınızın sterilizasyonunda hiçbir ödün vermemek için, 4A Medical ürünlerine güvenebilirsiniz.

Why Do 4A Medical Sterilization Control Products Make a Difference?

4A Medical Sterilization Control Products are an integral part of a healthcare institution's commitment to safety and quality. Advanced indicator technologies not only show whether a device is sterile but also guarantee the safety of your personnel and patients. For every institution seeking excellence in sterilization, 4A Medical is an accurate and reliable partner.

How Should a Sterilization Pouch Be Selected?

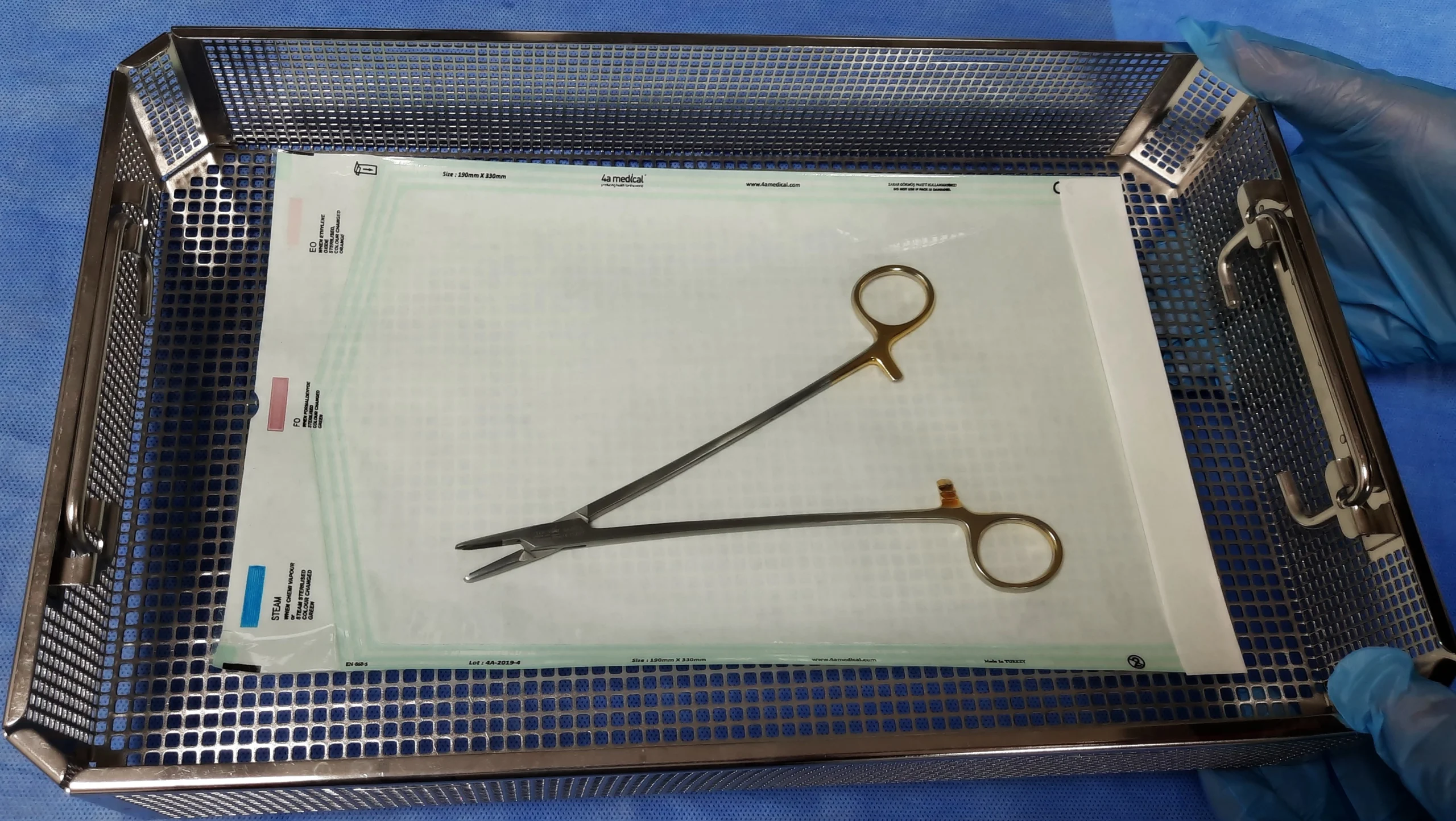

Sterilization pouches are recommended for packaging lightweight materials. The pouch must be the appropriate size for the product to be packaged and must have a suitable chemical indicator for the sterilization process. The sterilization pouch must allow chemical gas, heat, or steam to penetrate into the pouch during the sterilization process. Selecting an appropriate pouch size is critical; the packaged material should not strain the edges of the pouch and should not pose a risk of puncturing the material.

For products of various sizes, sterilization reels are preferred by users because they can be cut to the desired length. In this case, both ends of the piece cut from the sterilization reel will be open. The user will seal one end of the cut piece using a heat treatment, place the product to be packaged inside the resulting pouch, and then must seal the other end of the pouch with heat treatment.

The basis weight of the medical-grade Kraft paper used in sterilization pouches should be 60-70 gsm. Medical paper is porous to allow chemical gas and steam from the sterilizer to enter and exit the pouch during the sterilization process and must ensure these pores close during the drying process. Thus, by preventing viruses or bacteria from entering the pouch after the sterilization process, it must ensure that the material inside the pouch remains sterile.

How Should a Sterilization Pouch Be Packaged?

Materials should be placed inside the pouch with at least 2 cm of clearance from every edge. The materials should occupy no more than 70% of the pouch's total volume. Hinged instruments must be placed inside the pouch with the hinge in the open position. To prevent puncturing the paper section of the pouch, curved instruments should be positioned so that the curved part faces the plastic side of the pouch. Surgical instrument protectors should be used to prevent sharp-edged instruments from piercing the pouch.

A sterilization pouch is closed by applying a heat treatment with a sealing machine. Self-sealing sterilization pouches are closed using their own adhesive part without the need for an additional sealing machine. Excess air must be removed from the pouch before sealing.

How Should Sterilization Pouches Be Loaded into Autoclaves or Other Sterilization Machines?

Sterilization pouches can be placed horizontally on a shelf or positioned vertically in a row—with the paper and plastic sides facing the same direction—to allow for the circulation and penetration of chemical gas or steam within the sterilizer.

To prevent tearing after steam sterilization, sterilization pouches should not be touched until they are completely dry.

What is the Shelf Life of Sterilization Pouches After Processing?

Processed sterilization pouches should be stored at room temperature (24*C) or lower, in an environment with a humidity level below 70%. The shelf life of a processed sterilization pouch depends on the conditions; the material will maintain its sterility as long as the pouch does not get wet, torn, contaminated, or damaged. Note that manufacturers provide a specific shelf life and expiration date for their sterilization pouches. 4A Medical sterilization pouches maintain product sterility for 6 months following the sterilization process.

Can Sterilization Pouches Be Reused?

Sterilization pouches are single-use products and must not be reused. Damaged pouches should never be used for sterilization.

Why Should You Choose 4A Medical Sterilization Pouches?

-

Comprehensive Solutions: 4A Medical offers a variety of sterilization packaging solutions, including flat reels, gusseted reels, Tyvek® reels, reinforced reels, flat pouches, self-sealing pouches, gusseted pouches, Tyvek® pouches, and reinforced pouches. You can find the exact packaging product you need according to your required dimensions.

-

Expertise and Quality: 4A Medical provides services backed by over 20 years of experience and knowledge. Our sterilization pouches are manufactured in our own facilities using the latest technology. Our quality department monitors product quality at every stage, and we test every product lot before delivery.

-

Integrated Indicators: 4A sterilization reels and pouches feature three indicators on their edges for Steam, EO, and FO sterilization processes.

-

Specialized Designs: 4A Medical offers gusseted sterilization reels and pouches, which provide a larger internal volume for bulky materials.

-

High Resistance: For heavy products, we manufacture Tyvek® and reinforced sterilization reels and pouches, as they are more resistant to tearing.

-

Infection Control: Sterilization is a critical process for infection control, the importance of which has increased with COVID-19. Since 2019, the pandemic has demonstrated how vital hygiene, disinfection, and sterilization are. Therefore, the highest quality in every aspect, including raw materials, is necessary to achieve the best results. 4A Medical prioritizes quality starting from raw material selection, combining top-tier materials with the latest technology on the production line to produce the highest quality final products.